Single Screw pushes the limits of compression.

We have applied it to NH3 heat pumps.

Single Screw technology is the ultimate in compression.

Thanks to the balance of forces on the main rotor and vastly oversized bearings for the satellites, compressors developed on the basis of Single Screw are particularly able to withstand high differential pressures. The result is significantly lower maintenance frequencies than for other compressor technologies.

Vilter's Single Screw compressor is the basis for a successful investment in the decarbonisation of heat supply.

from 550 kW to 7600 kW

hot water at 95°C

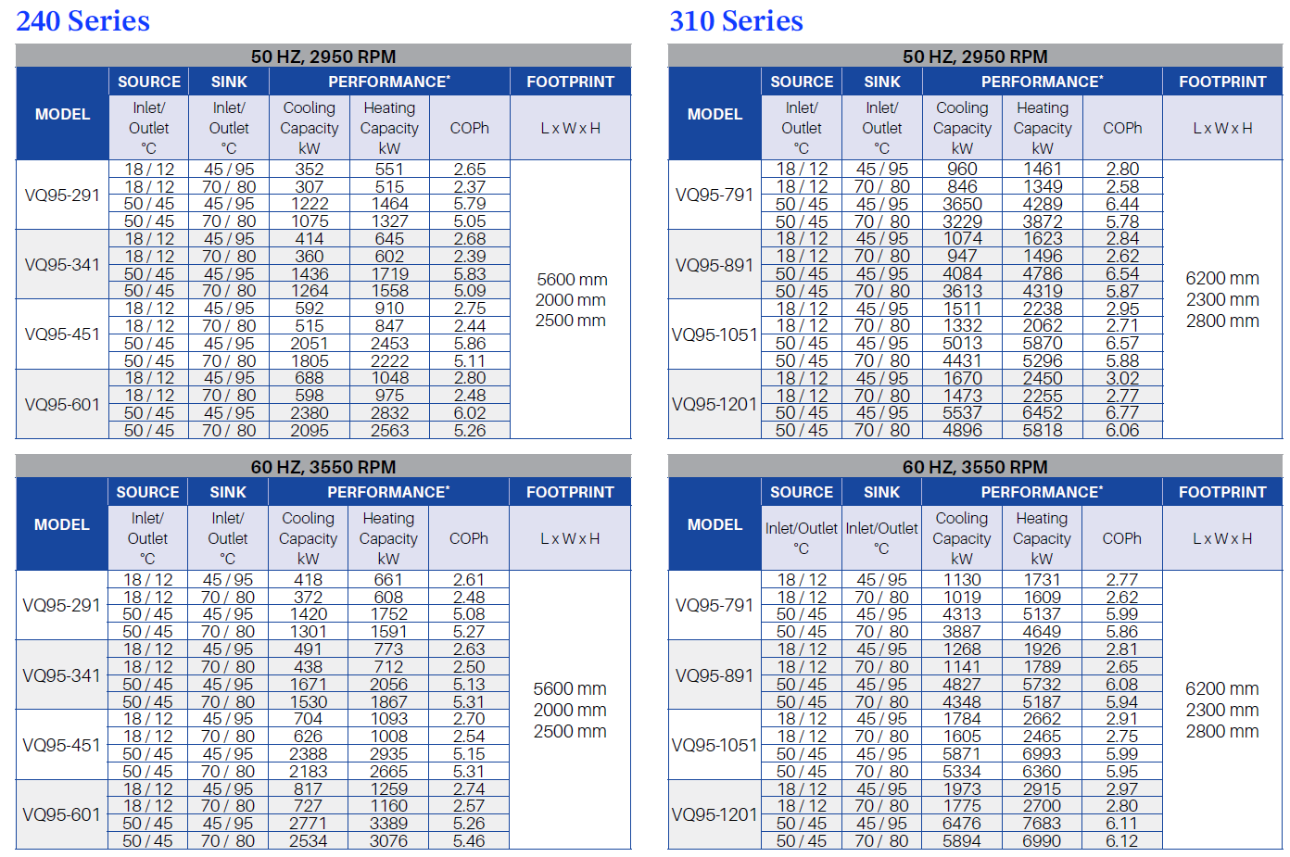

We offer a standardised range of heat pumps that can deliver between 550 and 7680 kW of heat per machine.

Standardisation of the range reduces investment, installation and commissioning costs.

Single Screw technology reduces operating costs.

soon water at 130°C!

Vilter continues to push the limits of Single Screw compressors. A new range of heat pumps has been launched, capable of delivering hot water at 130°C.

VQ95

Simplicity

The VQ95 is designed to minimise the usual complexities associated with the design, installation, commissioning, operation and maintenance of industrial heat pumps.

The system uses the intuitive, user-friendly controls of the Vission 20/20 PLC to make the VQ95 easy to operate and maintain. Single-stage units are inherently less complex and have fewer moving parts than multi-stage units. It can be serviced without removing the compressor from the skid. Maintenance is further simplified by an easy-to-reach access hatch on either side of the compressor.

Selection and configuration are streamlined thanks to Vilter's online software tool, which gives you a preliminary assessment and footprint based on your unique specifications...

Reliability

The VQ95 is a complete, single-stage NH3 machine that offers lower maintenance costs and longer service intervals, while guaranteeing the longevity of your operations.

The Single Screw compressor offers industrial-grade performance and reliability, with little or no performance degradation over time. Compared to other compressor technologies used in heat pumps, the VQ95 has fewer moving parts and longer bearing life.

Performance

The VQ95, equipped with the innovative Single Screw Vilter, exploits the properties of NH3, offering exceptional heating capacity and remarkable efficiency. Its distinctive metal-to-metal contact-free design ensures reliable performance throughout the product's lifetime, providing peace of mind for management and operational teams.

Our selection software is designed to seamlessly integrate the best component combinations, optimising the coefficient of performance (COP) and reducing the total cost of ownership for each application.

Thanks to its high COP and impressive lifting capacity, the VQ95 often eliminates the need for multi-stage systems, significantly reducing overall costs.

Flexibility

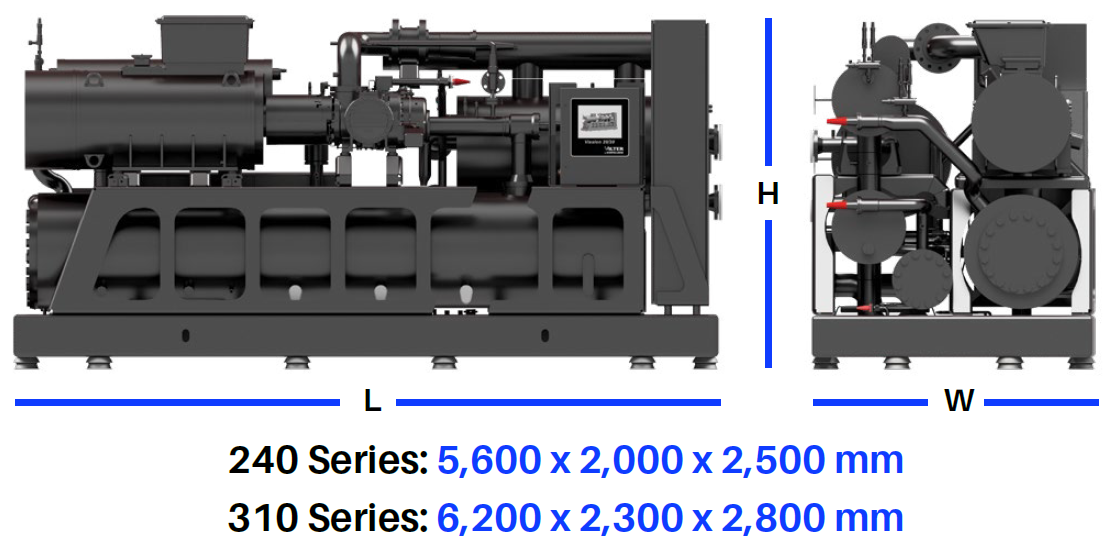

VQ95 heat pumps feature a flexible, modular and scalable design, engineered for seamless production, rapid installation and commissioning, and easy maintenance. A complete, optimised turnkey system is provided in a single frame design, without compromising ease of maintenance.

The VQ95 is available in two compact formats that support over 2,000 standard configurations, while offering greater capacity per skid to meet the demands of applications with fewer units.

- Option of high or low delta-T (ΔT) in the hot loop,

- The design of the system allows flexible source and discharge temperatures

Standard Performances

Standard Dimensions

VQ130

Let's keep in touch: the VQ130 range, supplying water up to 130°C, will be launched soon.

We can already respond to certain projects!

VQ130 + steam compressor

The latest development involves combining an industrial heat pump with mechanical vapour compression.

We can already respond to certain projects!