Low-temperature CO2 combined with ammonia for rejection or heat recovery makes a diabolically efficient and natural pairing for modern industrial refrigeration systems.

The cascade exchanger between these 2 fluids is one of the key parts of the installation: if it fails, the consequences can be harmful due to the formation of ammonium carbamate.

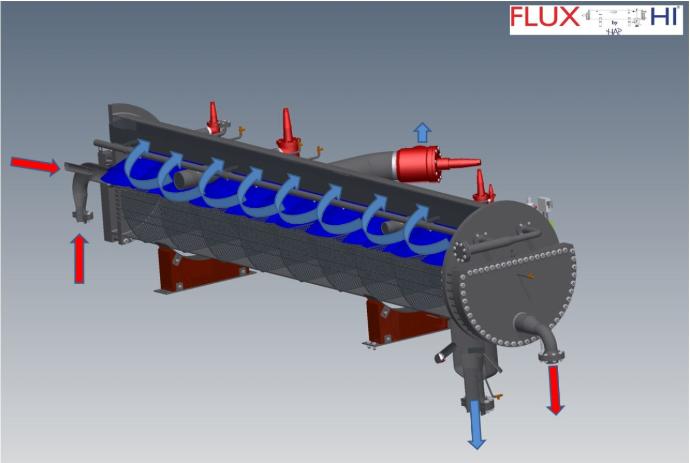

That's why we only offer solutions based on the Flux-Hi spray-chillers marketed by our subsidiary  .

.

These heat exchangers offer the best security for your business:

- even in the event of an internal leak, operations can continue despite the presence of ammonium carbamate in the calender;

- other parts of the installation, such as compressors and condensers, will not be affected, as the leak will remain confined to the spray-chiller calandria;

- but above all pressure tests, non-destructive testing and helium leak detection offer the best guarantee that no leak will occur;

- Heat treatment will prevent stress corrosion.

Complete solutions

On request, we can integrate our spray-chillers into packages with CO2 and NH3 pumps and a CO2 cylinder.

What's more, we can create transportable packages incorporating subcritical CO2 compressors, NH3 compressors and the cascade!